| Carpets have a long history… At the beginning it was something that was produced for personal use. Carpets provided warmth and protection in the tents while the motifs reflected emotions and personal stories… The technique of knotting and weaving carpets has developed over the years and the motifs became more and more detailed. It was nevertheless still a unique handicraft for private use.

In the 19th century, as industrialism gained momentum, the loom was also being developed, becoming more and more automated. More industrialized rug production began. In England, machine-knotted rugs were being produced on a major scale, in places like Axminster and Wilton, which is also the origin of these famous carpet types. Over the years, production techniques have become more sophisticated and today most rugs on the market are machine-knotted. Today’s machine-knotted rugs are of a high quality and a lot of the time it requires a trained eye to see the difference between a hand-knotted carpet and one produced mechanically. If you were to point out the biggest difference, it would be that machine-knotted rugs lack the soul behind the artwork that hand-knotted carpets have.

|

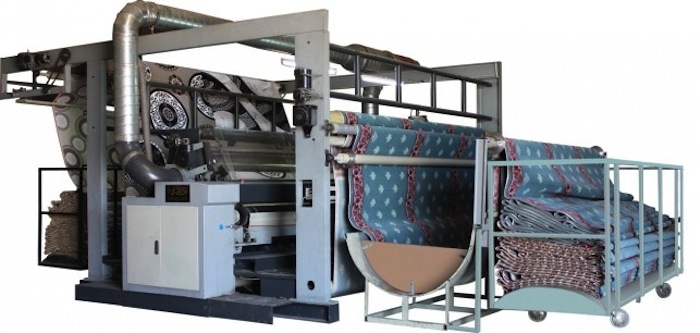

| Machine-knotted rugs are produced through thousands of reels of thread being fed into one giant mechanical loom, which quickly weaves the rug according to a chosen pattern. During production, which is carried out in fixed widths, different patterns and sizes can be produced simultaneously, which means minimal material spillage once the machine is running. There are however certain limitations, including the fact that only a certain number of colors can be used in one rug; usually between 8 and 10 colors can be combined and screened to produce a wider color spectrum. Once the rugs have been woven, the various patterns and sizes are cut apart, after which they are trimmed for the best possible durability. A number of rugs are also decorated with fringes afterwards, which are sewn onto the short ends, as opposed to the fringes being part of the rug’s warp threads as is the case in hand-knotted carpets. Producing a machine-knotted rug takes approximately one hour depending on size, compared to a hand-knotted carpet, which can take months and even years, which is also the main reason that machine-knotted rugs are significantly cheaper.

|

| Today there is an enormous range to choose from when it comes to machine-knotted rugs, both with regard to models and to quality. Choose from modern designs in a range of different colors and from oriental rugs with a range of different patterns. As production is mechanical, it is also easier to produce smaller collections quickly for select markets. Size-wise, the range is broad and it is usually easy to find the right rug in the desired size. Thanks to efficient production, the price of machine-knotted rugs is lower, which makes it possible to switch out rugs at home more often. Machine-knotted rugs are currently available in a range of different materials and material combinations. |