The carpet industry in the United States began in 1791 when William Sprague started the first woven carpet mill in Philadelphia. Others opened during the early 1800s in New England. Included in that area was Beattie Manufacturing Company in Little Falls, New Jersey, a company that operated until 1979.

In 1839, Erastus Bigelow permanently reshaped the industry with the invention of the power loom for weaving carpets. Bigelow’s loom, which doubled carpet production the first year after its creation and tripled it by 1850, is now part of the Smithsonian Institution’s collections. He continued to devote his life to innovation — 35 separate patents were issued to him between 1839 and 1876. Bigelow introduced the first broadloom carpet in 1877.

The power loom with Jacquard mechanism was developed in 1849, and Brussels carpet was first manufactured by the Clinton Company of Massachusetts. The Brussels loom was slightly modified, making possible the manufacture of Wilton carpet. Later, the Hartford Carpet Company joined with Clinton Company to become Bigelow Carpet Company.

In 1878, four Shuttleworth brothers brought 14 looms from England and established manufacturing facilities as the Shuttleworth Brothers Company in Amsterdam, New York. In 1905, the company introduced a new carpet, Karnak Wilton. Its instant success was phenomenal. Flooded with orders, a new building had to be constructed to exclusively handle Karnak production. Weavers worked four and five years without changing either the color or pattern on their looms. In 1920, Shuttleworth Brothers Company merged with another Amsterdam-based carpet manufacturer, McCleary Wallin & Crouse. They called the new company Mohawk Carpet Mills, after the Mohawk River that flows through the city.

Alexander Smith started his carpet manufacturing plant in 1845 in West Farms, New York. An American, Halcyon Skinner, had perfected the power loom for making Royal Axminster in 1876. He and Alexander Smith combined, forming a very successful carpet company. Alexander Smith was elected to Congress in 1878, but died on the evening of Election Day. Sixteen hundred people were employed at his factory at the time of his death. Alexander Smith & Sons continued. During World War I, the carpet looms were converted to make tent duck and navy blankets. In 1929 Alexander Smith & Sons was the largest manufacturer of carpets and rugs in the world.

Simulating The “Oriental” Rug

Industrialist/retailer Marshall Field had a traditional Axminster weaving loom modified to create what no one else had ever created — a machine-made rug woven through the back, just like a handmade Oriental, featuring intricate designs and virtually unlimited color variety. Karastan’s rug mill was established in 1926, and introduced the first Karastan rugs to the public in 1928. Alexander Smith, Bigelow, and Karastan are companies continuing today as divisions of Mohawk Industries, headquartered in Georgia. There are many manufacturers today producing both simulations of antique designs and updated “oriental” type rugs by both weaving and tufting processes.

The Tufted Carpet Industry: Born In The U.S.A. And The Pride Of Georgia

Through the late 1800s, Dalton, Georgia, struggled with cotton mills and steel manufacturing works to forge a small town in the north Georgia hills. Northwest Georgia, with its hard-packed clay, poor farmland, and rolling hills was among the last areas of Georgia settled. Rich in a heritage of Cherokee Indians and Civil War battles, that northern corner of the state was rugged and spawned people who were independent and self-sufficient. Those were the people who brought forth and nurtured the tufted textile industry. The industry’s infancy was in Dalton; it has gone through intense growth in Dalton; and it has now matured in and around Dalton. The carpet industry’s impact is great on this region, this state, and the nation; and the story of its growth is unique.

The Beginnings Of The Tufted Carpet Industry

The industry began in a simple way, around the turn of the century. A young, Dalton woman, Catherine Evans Whitener, recreated a bedspread in a hand-crafted pattern she had seen, for a wedding gift. Copying a quilt pattern, she sewed thick cotton yarns with a running stitch into unbleached muslin, clipped the ends of the yarn so they would fluff out, and finally, washed the spread in hot water to hold the yarns in by shrinking the fabric. Interest grew in young Catherine’s bedspreads, and in 1900, she made the first sale of a spread for $2.50. Demand became so great for the spreads that by the 1930s, local women, who were real entrepreneurs, had “haulers,” who would take the stamped sheeting and yarns to front porch workers. Often, entire families worked to hand tuft the spreads for 10 to 25 cents per spread. The local term for the sewing process was “turfin” for the nearly 10,000 area cottage tufters — men, women, and children. Bedspread income was instrumental in helping many area families survive the depression. As an example of the spirit of these early entrepreneurial women, Mrs. J. T. Bates stated that she simply “shipped 15 spreads to John Wannamaker’s department store in New York. On a piece of plain tablet paper I made out a bill for $98.15 and put it in with the spreads. Although there had been no previous contact whatsoever with the store, Wannamaker’s sent us a check for $98.15.” Chenille bedspreads became amazingly popular all over the country and provided a new name for Dalton: The Bedspread Capital of the World.

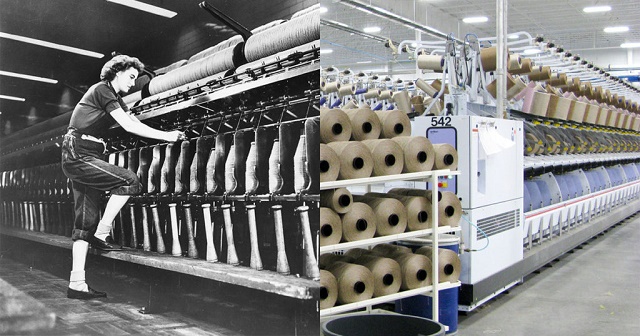

Mechanization – The 1930s

Buyer competition, which tended to lower the prices, the change in the minimum wage laws, and development of machine-produced spreads soon made the hand-crafted spreads too expensive. Gradually the industry began to pull the workers from surrounding hillsides and small towns into mills in Dalton, beginning the rapid growth of the mechanized tufting industry. In the 1930s, as a result of the demand for more bedspreads, the first mechanized tufting machine, attributed to Glen Looper Foundry of Dalton, was developed. Looper modified the single needle commercial Singer so that it would tuft the thick yarn into unbleached muslin without tearing the fabric and an attached knife would cut the loop. Machines quickly developed into four, then eight, twenty-four, and more needles to make the parallel rows of tufting known as “chenille.” By 1941, all but about one percent of tufted bedspreads were machine made. Mats and rugs were created with the same process, using cotton yarns and fabric. Volume increased rapidly after World War II, because people were hungry for color and beauty. To show the extent of growth, 30,000 bales of cotton were consumed in 1946 by the industry. By 1950, approximately 500,000 bales were used, and the industry was the third largest consumer of cotton grown in Georgia in 1952.

Synthetic Fibers Are Introduced

Until about 1954, cotton was virtually the only fiber used in tufted products. Wool and manmade fibers — polyester, nylon, rayon, and acrylics — were gradually introduced by textile men in Dalton. Nylon was first introduced in 1947 and grew steadily to dominate the market. Polyester was first used in 1965 and was followed soon by polypropylene (olefin). Most manufacturers will agree that the single most important development in the industry was the introduction of bulk continuous filament nylon yarns. These yarns provided a luxurious quality, durable carpet, similar to wool, which was more economical to produce. Therefore, a durable, luxury product was offered to the consumer for less money. In 1950, only 10 percent of all carpet and rug products were tufted, and ninety percent were woven. However, about 1950, it was as if someone had opened a magic trunk. Out of that trunk came man-made fibers, new spinning techniques, new dye equipment, printing processes, tufting equipment, and backing for different end uses. Today, tufted products are more than 90 percent of the total, followed by less than 2 percent that are woven, and 6.7 percent for all other methods, such as knitted, braided, hooked, or needlepunched. By 1951, the tufting industry was a $133 million per year business made up primarily of bedspreads, carpet, and rugs, with carpet accounting for $19 million. The industry broke the billion dollar mark in 1963. Through the years, the Dalton area has continued to be the center of the tufted carpet industry, and today, the area produces more than 70 percent of the total output of the world-wide industry of over $9 billion. Dalton is now known as the “Carpet Capital of the World.”

Quick Facts About The US Carpet Industry

- Carpet accounts for 51% of the total U.S. flooring market.

- The carpet and flooring industry employs 29,830 workers in 227 establishments in Georgia with a payroll topping an estimated $3 billion – the largest of any manufacturing sector in the state.

- Georgia is also home to 9 of the top 20 carpet manufacturers in the U.S.

- On the list of the top 50 manufacturers of all U.S. floor covering, there are 14 carpet manufacturers located in Georgia.

- More than 85% of the U.S. carpet and rug market is produced by mills located within a 65-mile radius of Dalton, for an estimated $8 billion in business activity.

- Georgia supplies more than 45% of the world’s carpet and rugs.

- In 2015, CARE (Carpet America Recovery Effort) members diverted 520 million pounds of carpet from the landfill. (In 2013, CARE initiated a newer and more accurate method of counting collections.)

- In 2015, CARE members recycled 157 million pounds of carpet.

- Since it was founded in 2002, CARE members have diverted over 4 billion pounds of post-consumer carpet from landfills in the United States.